Automation is the technology that uses control systems such as logic circuits or computers, to handle machines and processes, thus reducing the need for human intervention. In the industry, automation is applied in virtually all sectors, with the advent of electronics, that has allowed to pass from the pure mechanics to the possibilities offered by electronics and automatic controls. One of the branches of automation is robotics, or the science that through the study of intelligent beings, creates methodologies that allow a machine (called robots) to perform specific tasks.

The so-called robot are actually manipulators that let you perform specific tasks, from simple actions, such as welding, to other more complex, like painting, where you need to know how to follow the contours of each object. These machines are multifunctional, automatically controlled, reprogrammable, they consist of a series of segments connected by joints with different degrees of freedom, fit to take and/or move objects.

The theoretical aspects of industrial robots have been studied by Denavit and Hartenberg, who already in 1955 established a kinematic model common to all manipulators, using appropriate parameters, such as link lengths and angles of joints through which it was possible to construct matrices for calculating the movements of mechanical arms. The study of this type of electronic design would open the way for methods of calculating the trajectory easily implementable on computers.

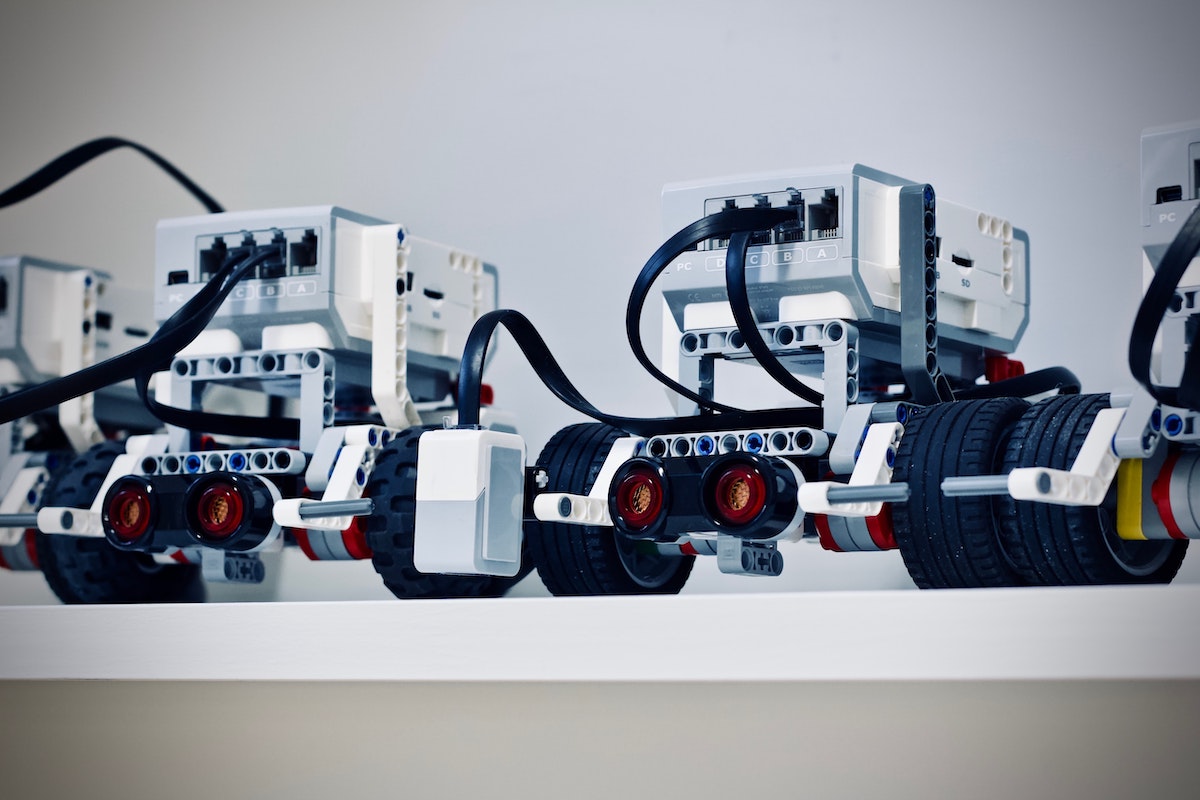

The use of these industrial manipulators has obviously changed a lot over the years and especially with the evolution of automation. The first application examples date from the ’60s, thanks to Unimation, a company that designed the first robot manipulator suitable for welding points, a very simple function, but it was only the beginning. Until the ’70s, however, the insufficient use of these robots was also due to the fact that they worked with hydraulic devices and were therefore not at all accurate in their tasks.

A major step forward came with the design and creation of Stamford Arm robots from the University of Stamford and PUMA (Programmable Universal Machine for Assembly) always by Unimation. These new robots, completely electric, were much more advanced than their predecessors. Since then the evolution of robotic has been very fast and continuous, with innovative proposals each year.

Also now the robotics has applications in many fields, not just the industry, which still remains the most important part. There is for example the home automation, or robotics used in domestic environments. The biorobotics includes those robots used in the medical field, military robotics, while not as developed as in the movies, used mostly with reconnaissance and surveillance purposes among which there are such as unmanned aircraft called drones. The space robotics, however, even if develops technologies and methods for the use of robots out by the atmosphere this field of robotics has reached the useful results in fields outside the space research. Examples of these robot are the probes, used in several exploratory missions on the planets of the solar system.